|

|---|

Construction Industry

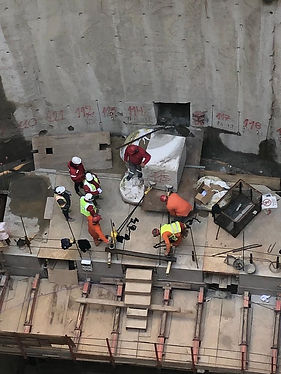

Unleashing Cutting Power in Diverse Construction Materials

In the fast-paced world of construction, Diamond Pauber's diamond wires are meticulously designed to tackle the challenges posed by various construction materials, including Plain Concrete, Heavily Reinforced Concrete, and Steel.

Our commitment to innovation and precision ensures that our diamond wires not only meet but exceed the demands of the construction industry, providing optimal solutions for various cutting challenges.

Choose the Best Diamond Wire for

Your Construction Projects

-

ORZ-C 42HA Hybrid: known as "Easy Cutting" diamond wire, this is a versatile tool designed to handle multiple applications, providing high adaptability and efficiency.

-

LSR-C 40HA: appreciated for its exceptional speed, it is the preferred choice when efficiency is a must. This diamond wire is partcularly suitable for experienced professionals who demand high levels of productivity.

-

SEP-T 48HA (SwiftEdge-PRO) & MSP-K 48HA (MetalSlash-PRO): these 2 diamond wires excel on construction site, cutting both concrete and steel and offering reliable and efficient performance on your construction dismantling projects. Moreover, they are complementary, with MetalSlash-PRO serving as a reliable backup in case the SwiftEdge-PRO wire breaks during cutting. Thanks to its smaller diameter, MetalSlash-PRO can be easily inserted into the previous cut made by SwiftEdge-PRO, minimizing interruptions and allowing work to resume quickly.

For your decommissioning projects, click here for our dedicated page.

Diamond Wires | Type and dimension | Description | Image | DataSheet | ViewOrder |

|---|---|---|---|---|---|

ORZ-C 42HA “Hybrid” for Concrete Cutting | Electroplated Tapered ø9,8mm - 42 BPM | ORZ-C 42BPM Hybrid is an Electroplated diamond wire with tapered shaped beads able to cut any kind of concrete, from plain to heavly reinforced concrete. Due to its particular shape this diamond wire gives the maximum cutting speed and a longer life. ORZ-C 42BPM Hybrid is assembled with the exclusive SHX polimeric coating able to protect the steel rope in any application. The HA Special Assembly wiht High Resistance can be applied in any cutting condition without problem This diamond wire is assembled with 42 beads per meter. | > DataSheet | 20 | |

LSR-C 40HA "Pro" for Concrete Cutting | Electroplated Tapered ø9,9mm - 38÷42 BPM | LSR-C is an Electroplated diamond wire with tapered shaped beads able to cut any kind of concrete, from plain to heavly reinforced concrete. Due to its particular shape this diamond wire gives the maximum cutting speed and a longer life. LSR-C is assembled with the exclusive SHX polimeric coating able to protect the steel rope in any application. HA Assembly Normally this diamond wire is assembled with 38 ÷ 42 beads per meter. | > DataSheet | 18 | |

SEP-T 48HA "SwiftEdge-PRO" for Steel Cutting | EP Diamond wire, Tapered shape 10,8mm UsMesh 25/30 | SEP SwiftEdge-PRO diamond wire is specifically designed for cutting steel structures, offering high cutting speed and increased productivity. The 10.8mm diamond beads, made with UsMesh 25/30 diamond type and Oriented Crystal® technology, provide optimal cutting performance. Assembled with 48 beads per meter (48 BPM) and coated with the exclusive SHX polymeric elastomer, SEP SwiftEdge-PRO diamond wire offers enhanced strength, flexibility, and improved cutting efficiency. The SHX assembly with the polymeric elastomer coating ensures a durable and reliable wire that can withstand the rigors of steel structure cutting. Choose SEP SwiftEdge-PRO diamond wire for fast and efficient steel cutting, enabling you to meet your project timelines and maximize productivity. Experience the cutting-edge performance of our diamond wire, featuring the unique combination of 48 BPM assembly and the SHX polymeric elastomer coating. | > DataSheet | 16 | |

MSP-K 48HA "MetalSlash-PRO" for Concrete & Steel Cutting | EP Diamond wire, Tapered shape 9,8mm UsMesh 40/50 | MSP MetalSlash-PRO diamond wire is specifically designed for cutting metal structures, offering superior performance and exceptional durability. The 9.9mm diamond beads, made with Oriented Crystal® technology, deliver powerful cutting action and superior strength. Assembled with 48 beads per meter (48 BPM) and coated with the exclusive SHX polymeric elastomer, MSP MetalSlash-PRO diamond wire provides optimum cutting efficiency, flexibility, and enhanced durability. The SHX assembly with the polymeric elastomer coating ensures a strong and reliable wire that can withstand demanding metal cutting tasks. Choose MSP MetalSlash-PRO diamond wire for precision, reliable, and uncompromising metal cutting. Experience higher levels of performance and satisfaction with our premium-quality diamond wire, featuring the unique combination of 48 BPM assembly and the SHX polymeric elastomer coating. | > DataSheet | 4 |

Cutting Excellence Redefined: Where Experience Shapes Revolutionary Technologies

Our unparalleled expertise and dedication to innovation enable us to offer a cutting-edge #CuttingExperience that maximizes efficiency, delivers superior results, and contributes to a more sustainable future. With our diamond wire solutions, customers can confidently tackle their most demanding cutting projects, knowing they have a trusted partner committed to excellence.

Advanced Electroplated Diamond Wires for Cutting Applications

Our electroplated diamond wires have proven to be the ideal solution for various cutting tasks, particularly in challenging environments and sensitive areas. These cutting-edge wires are highly effective in cutting through structures such as bridges, dams, floors, jetties, columns, and concrete pipes, even in restricted and delicate settings.